Eccentric Roll Crusher ERC® FLSmidth

Throughputs of up to 8,000 metric tons per hour along with a particularly high crushing intensity are no problem for this mining roll crusher. This is the result of its innovative and

McLanahan Roll Crushers

Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability

Roll Crusher - an overview ScienceDirect Topics

These dig into the rock so that the action is a combination of compression and ripping, and large pieces in relation to the roll diameter can be handled. Toothed crushing rolls

New insights into double roll crushing - ScienceDirect

2023年11月1日 Introduction. Comminution between counter-rotating rolls is a well-established principle. In coarse comminution, double roll crushers (DRC) are used for the

Roll Crushers Williams Crusher

Features. Ash Crusher. Williams Crusher Dimensions. Roll Crusher Applications. These machines can handle a wide range of materials, including: Bauxite. cement clinker. chalk.

Long-lasting roller crusher and sizer solutions I FLSmidth

Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in

New insights into double roll crushing - ScienceDirect

2023年11月1日 In coarse comminution, double roll crushers (DRC) are used for the size reduction of blasted materials and in secondary comminution. In the primary crushing

Toothed Roll Crusher Roller Crusher Manufacturer

2024年3月27日 Description. Toothed roll crusher is designed for crushing fragile materials with medium hardness or less, especially for crushing raw coal in large coal mines or

Toothed Roller Crusher - Hongxing Mining Machinery

2024年2月19日 Product. image. presentation. Toothed Roll Crusher Roll Crusher. Compared with the roller crusher, the toothed roller crusher has a larger capacity of 30

IOP Conference Series: Materials Science and Engineering

element method to model the performance of a cone crusher comminution machine has been explored using the particle replacement method to represent the size reduction of

Toothed Roll Crusher - Zoneding Machine

3 天之前 200-300. 6P 75×2. 38.6. 8010×4500×2050. Get Price And SupportWhatsapp+8618637198006Email:[email protected] PriceLeave a message Toothed Roller Crusher Introduction Applied fileds of toothed roller crusher Working Principle of Toothed Roll Crusher Motor of Toothed Roll Crusher The toothed roll crusher offers

New insights into double roll crushing - ScienceDirect

2023年11月1日 Double roll crushing is a comminution principle that has already been deployed for more than 100 years. It is known for high throughputs of sometimes sticky materials such as overburden. However, its applicability for ore and hard rock processing has been underestimated in recent decades. The presented research results are suitable

Introduction of Toothed Roll Crusher – Luoyang

2024年4月21日 Toothed roll crusher has large capacity, high production efficiency and low noise, especially for river pebbles with great crushing effect. Luoyang Dahua is a large toothed roll crusher manufacturer, for

Toothed Roll Crusher For Coal Preparation Plant - FTM

1 天前 Toothed roll crusher is widely used in coal, metallurgy, mining, chemical industry, building materials, and other industries, and it is more suitable to crush coal in large coal preparation plant and process waste. Toothed roll crusher has a high crushing capacity. The distance between the rollers can be adjusted by hydraulic pressure.

Mining Crushers AllMinings

2023年12月5日 A mining crusher is a machine used to reduce large rocks into smaller pieces. Crushers are designed to handle a range of materials. It is from ores to coal and various minerals used in the mining industry. There are several types of crushers commonly used in mining operations: Jaw Crusher. Gyratory Crusher.

Coal Crushing: New-type Toothed Roll Crusher VS

2022年3月22日 Traditional toothed roll crusher is usually driven by double-motors. Two sets of motors, couplers and reducers are adopted to drive the independent rollers so that the rollers have the power to crush large coal materials. Traditional toothed roll crusher structure. The coupler is applied between reducer and rolls to transfer torque.

Toothed Roll Crusher PDF - SlideShare

2017年2月22日 2. The Application and Description of Roller Crusher: The Performance Characteristics of Roller Crusher: Roller crusher is suitable for crushing raw coal in coal, metallurgy, mine, chemistry and building materials industry especially in large coal mines and coal dressing plants. Roller 1. It is equipped with hydraulic automatic yielding device

Eccentric Roll Crusher ERC® FLSmidth

3,250- 6,550. 3,450- 6,900. 3,650- 7,300. 1) Crusher capacity calculated based on a typical run-of-mine feed material with an average raw density 2.6t/m3 and max. feed size less or equal to 80% of crusher feed opening. Actual values are depending on feed material characteristics (e.g. hardness UCS, feed particle size distribution, moisture ...

Fine Crushing Plant With Roll Crushers - Eastman Rock Crusher

2022年5月20日 Double Toothed Roll Crusher Introduction. The double toothed roll crusher is equipped with two toothed rolls. The toothed roll surface is divided into large (small) wolf teeth, special teeth for coke cutting, ring teeth, straight teeth, large plate teeth, etc. it is suitable for medium or coarse crushing occasions where the particle size of finished

Advantages and Disadvantages of Roll Crusher - Knowledge

Advantages of Double-Roller Crusher. 1. In the production, the crushing range of double roll crusher is wide. Whether it is coal or large ore, as long as the material with Mohr hardness below 9 can be crushed by this machine. 2. The speed of finished products of toothed roll crusher is extremely fast.

Double Roll Teethed Roll Crusher - 911

2016年2月24日 The range of the smooth-face rolls, for example, is from about 400 ft/min for the small 12-in. rolls, to 2000-2200 feet/minute for the heavy-duty 72″ machine. The single-roll crusher has a tip speed of 400

Roll Crushers - Top 2022 Models - 911 Metallurgist

4 天之前 Progress in Roll-Crushing. BY C. Q. Payne, New York, N. Y. On the right, a Roll Crushers is shown in a sectional elevation of the A-C single-roll crusher while here below is a cutaway view of the machine, with

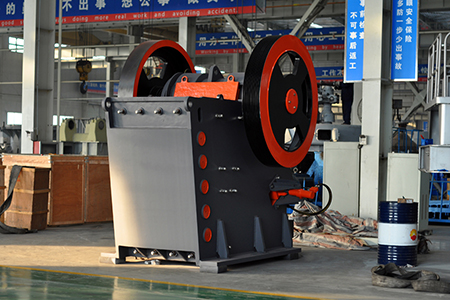

Toothed Roll Crusher Roller Crusher Manufacturer

2024年3月27日 Toothed roll crusher is designed for crushing fragile materials with medium hardness or less, especially for crushing raw coal in large coal mines or coal processing plants. It is widely used in coal, metallurgy, mining, chemical industry, building materials, etc. It has the characteristics of small size, large crushing ratio, low noise, simple ...

Bulk-buy Large Toothed Roll Coal Crusher with Uniform

Bulkbuy Large Toothed Roll Coal Crusher with Uniform Particle Size for Coal Mine price comparison, get China Large Toothed Roll Coal Crusher with Uniform Particle Size for Coal Mine price comparison from Roller Crusher, Crushing Machine manufacturers suppliers on Video Channel of Made-in-China.

Toothed Roller Crusher - Hongxing Mining Machinery

2024年2月19日 The toothed roller crusher is suitable for crushing raw coal in coal, metallurgy, mine, chemistry and building materials industry especially in large coal mines and coal dressing plants. Roller crusher has very big crushing ability, and the electromotor is connected with the reducer with Limit type hydraulic coupler to prevent dynamic

Maintenance Guidelines for Double Toothed Roll Crusher

2023年8月9日 The double toothed roll crusher must be started without load, and the remaining materials in it must be checked and removed before starting. If the double-toothed roller crusher is not used for a long time or is started for the first time, the large pulley should be rotated 2-3 times before starting the motor.

Supply Toothed Roll Crusher Customized Factory - Sinoma

Toothed Roll Crusher. Brand Sinoma-Liyang. Product origin Liyang, Jiangsu, China. Delivery time 7 months. Supply capacity 10-800tph. 1. The tooth roller crusher has become the preferred equipment of the thermal power plant with the advantages of efficient, energy-saving, environmental protection. Suitable for crispy materials below 40MPa, such ...

Optimization of particle size distribution in circulating fluidized ...

2019年6月15日 Next, the two-toothed roll crusher was optimized based on the framework proposed by the Whiten model. The reasonable rolls gap and teeth length should be 75 mm and 23 mm, respectively. Further, a physical model of a two-toothed roll crusher was established to obtain the optimized roll diameter; it was later found to be >660 mm.

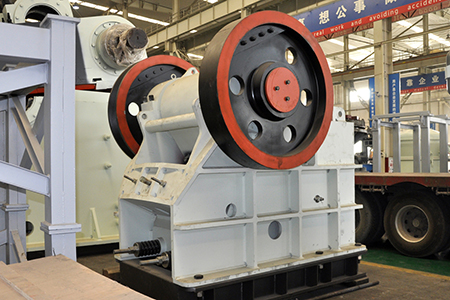

Toothed Roll Crusher

2022年8月29日 The Application and Description of Toothed Roll Crusher: Roller crusher is suitable for crushing raw coal in coal, metallurgy, mine, chemistry and building materials industry especially in large coal mines and coal dressing plants. Roller crusher has very big crushing ability, and the electromotor is connected with the reducer with Limit type

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 A gyratory crusher works by compressing the coal between a mantle and a fixed concave liner, similar to a cone crusher. 3. Double toothed roll crusher. The double toothed roll crushers are one of the most economical and practical medium and fine crushers. They are very popular among small coal processing plants.